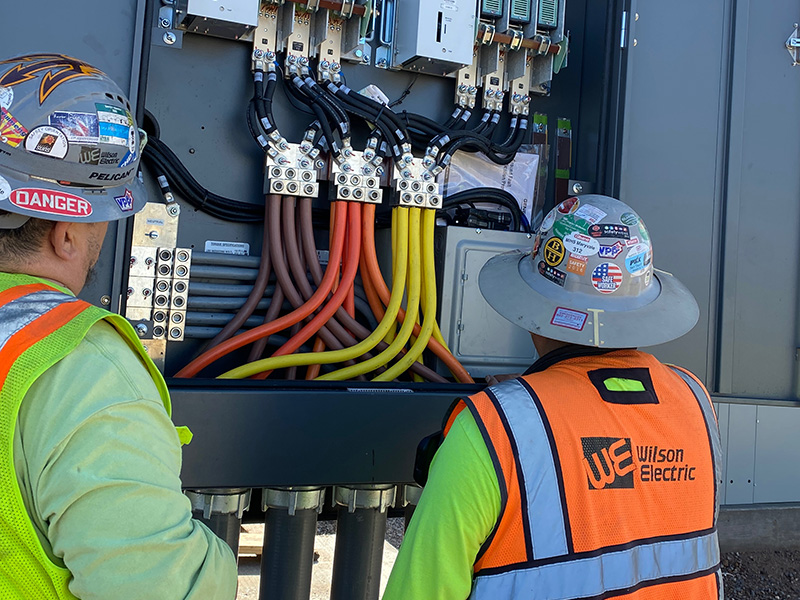

Preventative maintenance on your schedule

Just like any other high-performance machine, electrical systems need regular preventive maintenance and monitoring to keep them running safe and sound. Inadequately maintained electrical systems are a leading cause of business interruption, poor energy efficiency, fires, equipment wear-out, and breakdowns, all costly problems. Regular and routine maintenance is extremely important. Preventive maintenance should be performed at least every three years.

An effective electrical preventative maintenance program can reduce your risk of unscheduled outage by as much as 66% according to the statics from the Institute of Electrical and Electronic Engineers. Focus your electrical preventive maintenance program on the most common and frequent problems leading to electrical fires and equipment failures. This includes inspections and preventive measures to ensure electrical apparatus is kept clean, cool, dry, and tight. Electrical system maintenance increases safety and decreases losses.

Reduce downtime, increase longevity

We can save you money by reducing downtime, maintaining existing equipment, and increasing equipment longevity. We help you adapt to your ever-changing power needs using the most current technology, including:

- Thermography to identify potential electrical equipment issues. This non-invasive scanning can increase the reliability and efficiency of equipment, reducing breakdowns and stoppages and significantly reducing maintenance costs and production losses.

- Power Quality Tests

- HIPOT Testing provides in-depth reports that determine deterioration levels of electric insulation and help maintain personal safety and power reliability.

Maintenance & Repair

Our commercial electrical preventative maintenance and repair services include the following:

- Gear and Panel Service

- Solar Power Maintenance

- Scheduled Maintenance

Ready to build your next project? Let’s Talk. Contact Us